Purpose

Weighing systems currently on the global market are outdated, as they do not allow for automation and real-time data tracking. The need to upgrade these systems has appeared on the market, as we are in the digital age, where it is unacceptable that data is still read and transcribed by a manual worker. In addition, due to the environmental protection policy, which tightens the conditions for CO2 emissions into the environment, more and more cargo is being moved from roads to other types of transport, such as rail, ship and air transport, which is why countries are increasingly investing in railway infrastructure and the computerization of railway freight transport.

The purpose of our project is to facilitate and improve the user experience of the weighing system, which will enable the user to review the data, to be aware of what is happening with his train composition (in terms of weight and length) and where he is at every moment of the journey. In this way, big savings will be made possible, more accurate data that is available at any time (online) and more accurate forecast times of cargo arrival. Our company is upgrading the weighing system with an application that will enable faster automated data transfer via the weighing cells, at a higher driving speed through the cells, to the application and then to the system or database. Easier inspection and tracking, anytime and anywhere in the world (online).

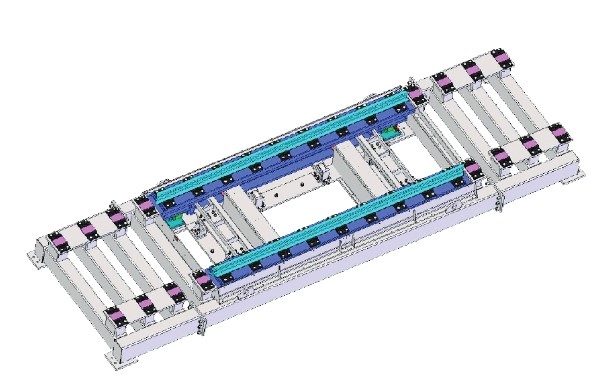

Track scale

The system for automatic dynamic track weighing and measurement of train compositions enables the weighing of locomotives and wagons during the actual movement process. Weighing cells are connected to the application, into which data on the weight and length of the entire composition (train, locomotive) are transferred and include other data on the characteristics of the wagons and the locomotive. Data transfer is fully automated, users are enabled to track cargo in real time anywhere and anytime (online).

Thanks to the obtained co-financed funds, the train composition will run faster than before through the weighing cells. More accurate weighing is possible and due to automation, there is no possibility of errors in reading the data.

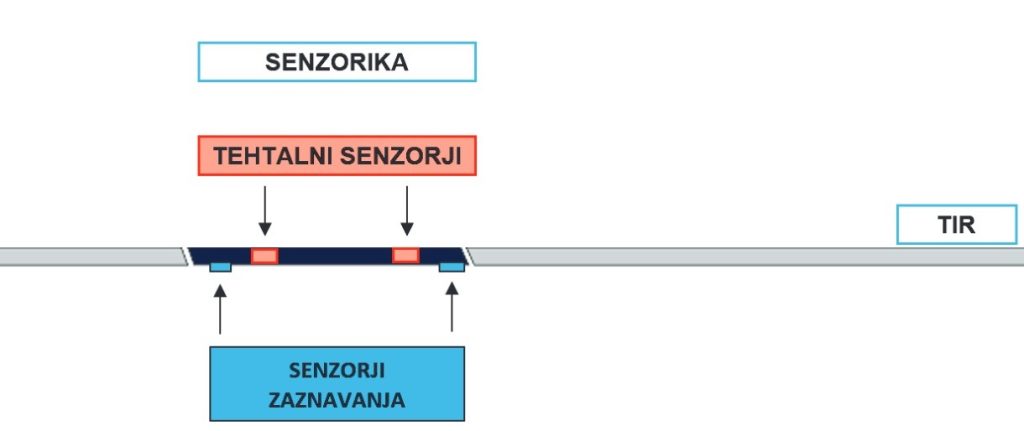

System operation

- AUTOMATIC DETECTION AND IDENTIFICATION OF WAGONS

- TRANSPORT AT SPEEDS UP TO 10 KM/H

- REMOTE MONITORING IN REAL TIME

- TO THE EXISTING NARROW AND WIDE GAUGE SYSTEM

- AXIAL WEIGHING TAKES LITTLE SPACE

Video presentation

Send a request

All rights reserved © 1994 – 2023 ETRA d.o.o